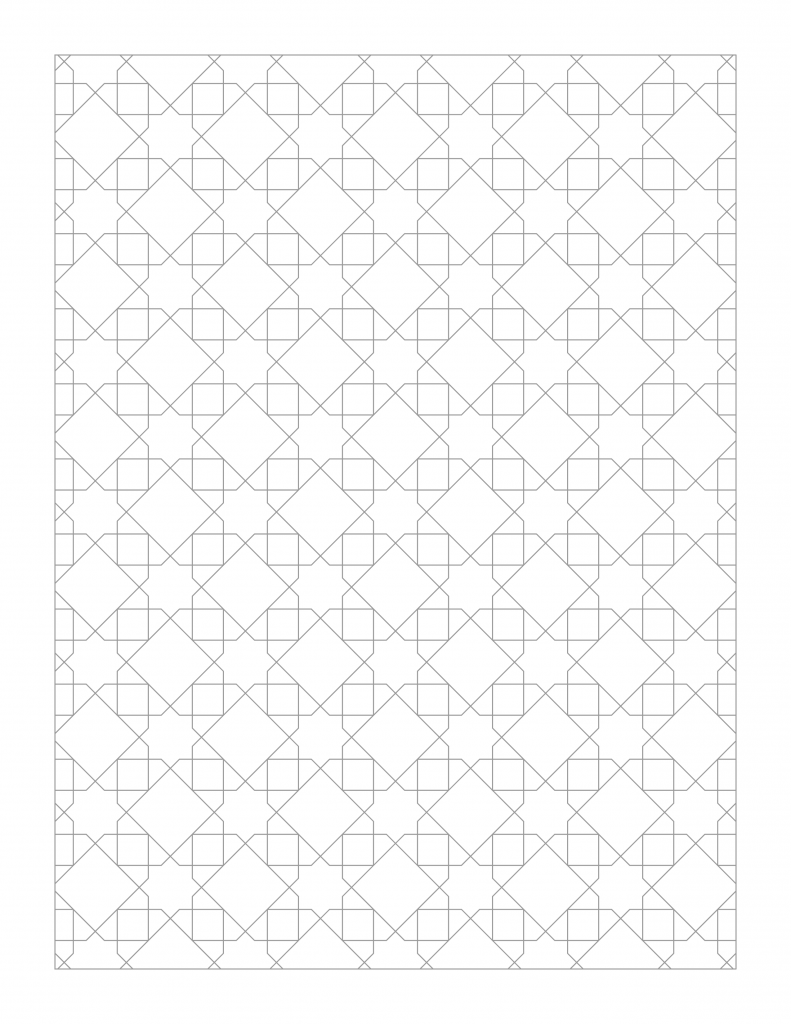

PDF, too, if you like such things: record_label_jali.pdf. Made with OpenSCAD.

PDF, too, if you like such things: record_label_jali.pdf. Made with OpenSCAD.

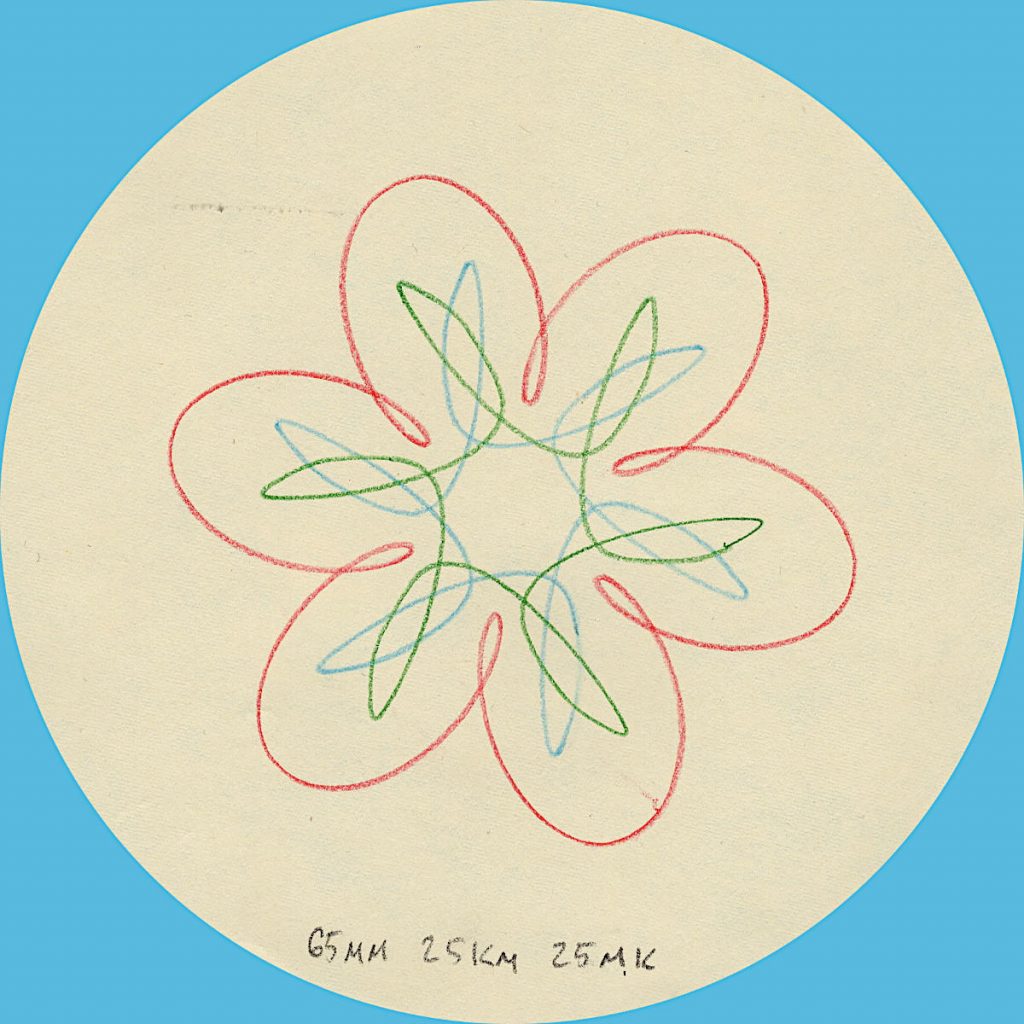

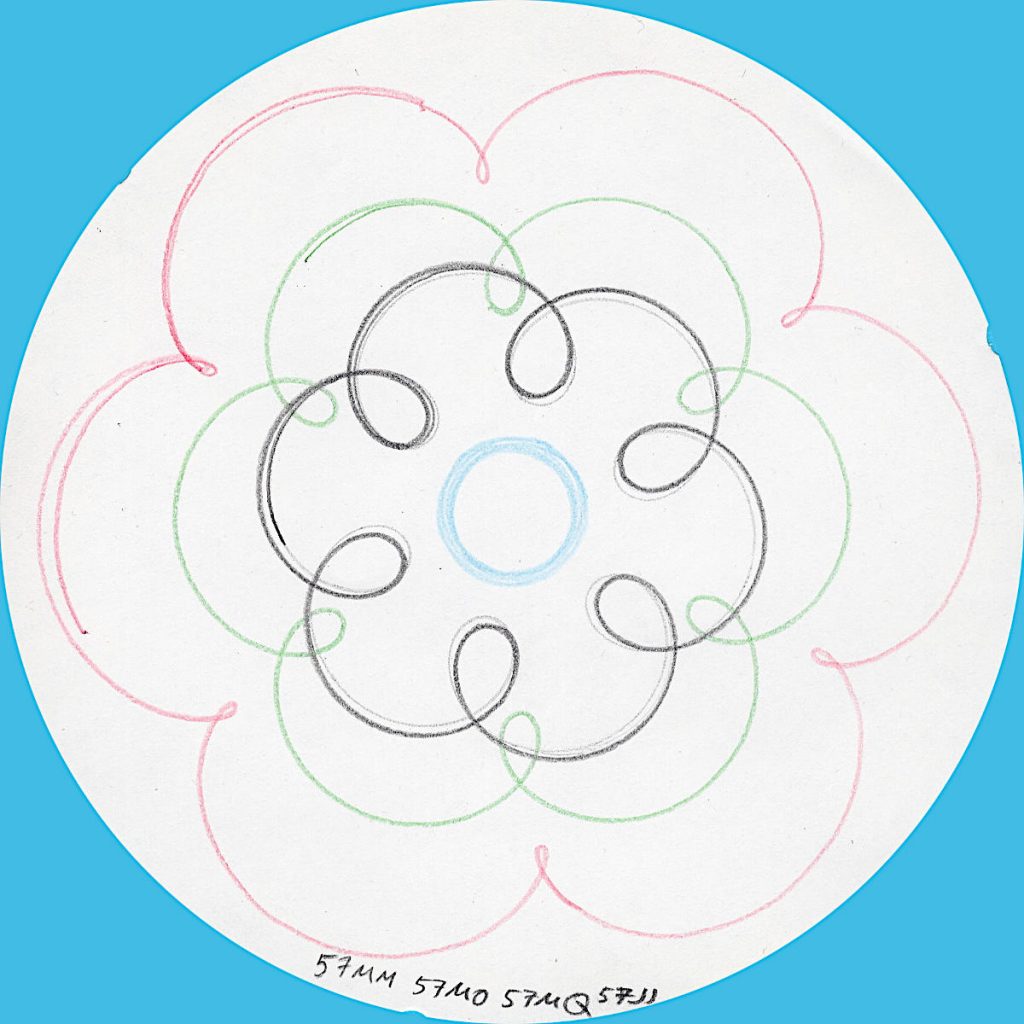

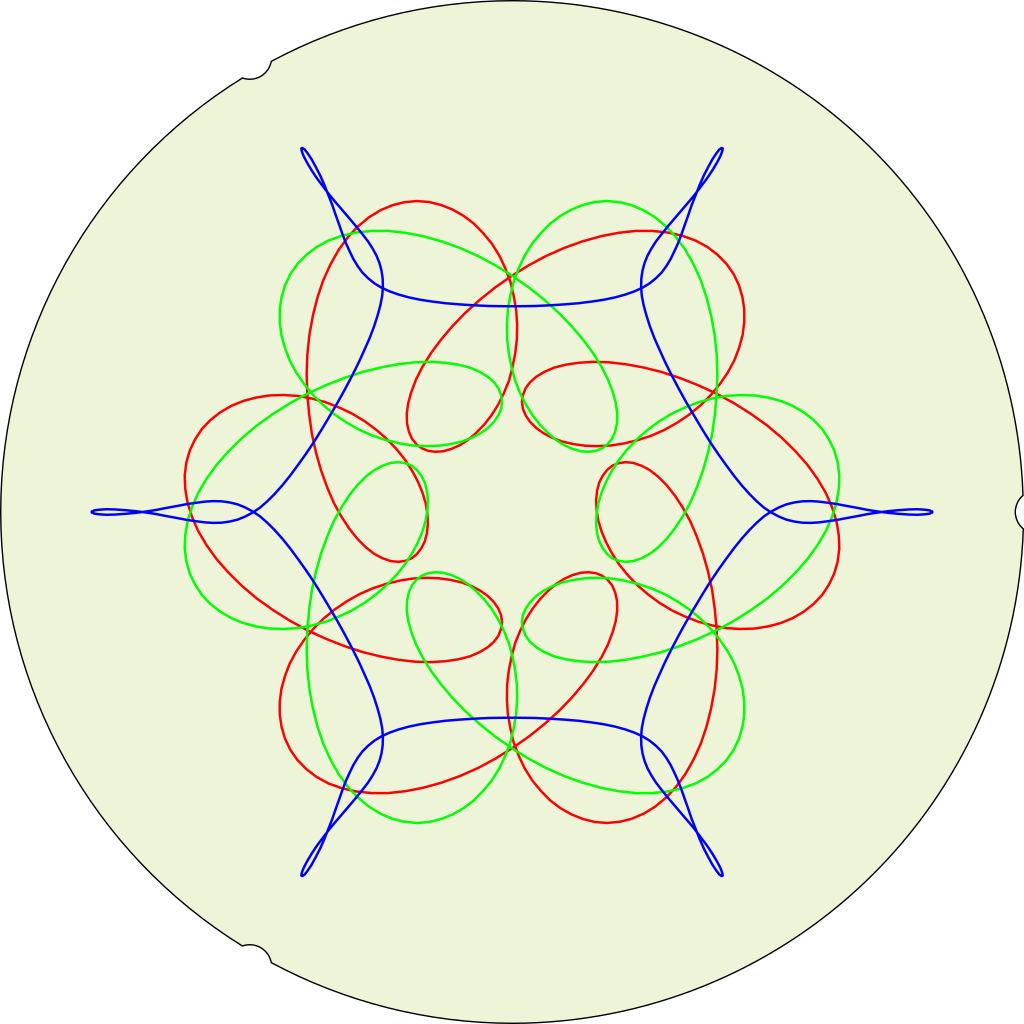

Simulated (and not quite right yet) output from a “HOOT-NANNY” or Magic Designer, a proto-Spirograph toy that drew six-sided curves on round paper sheets. It was made by Howard B. Jones and Co. of Chicago, IL and first sold in 1929. The company’s better known for producing Jones Plugs and Sockets, sometimes known as Cinch-Jones connectors. The “HOOT-NANNY” name was dropped when production moved to the Northern Signal Company of Saukville, WI.

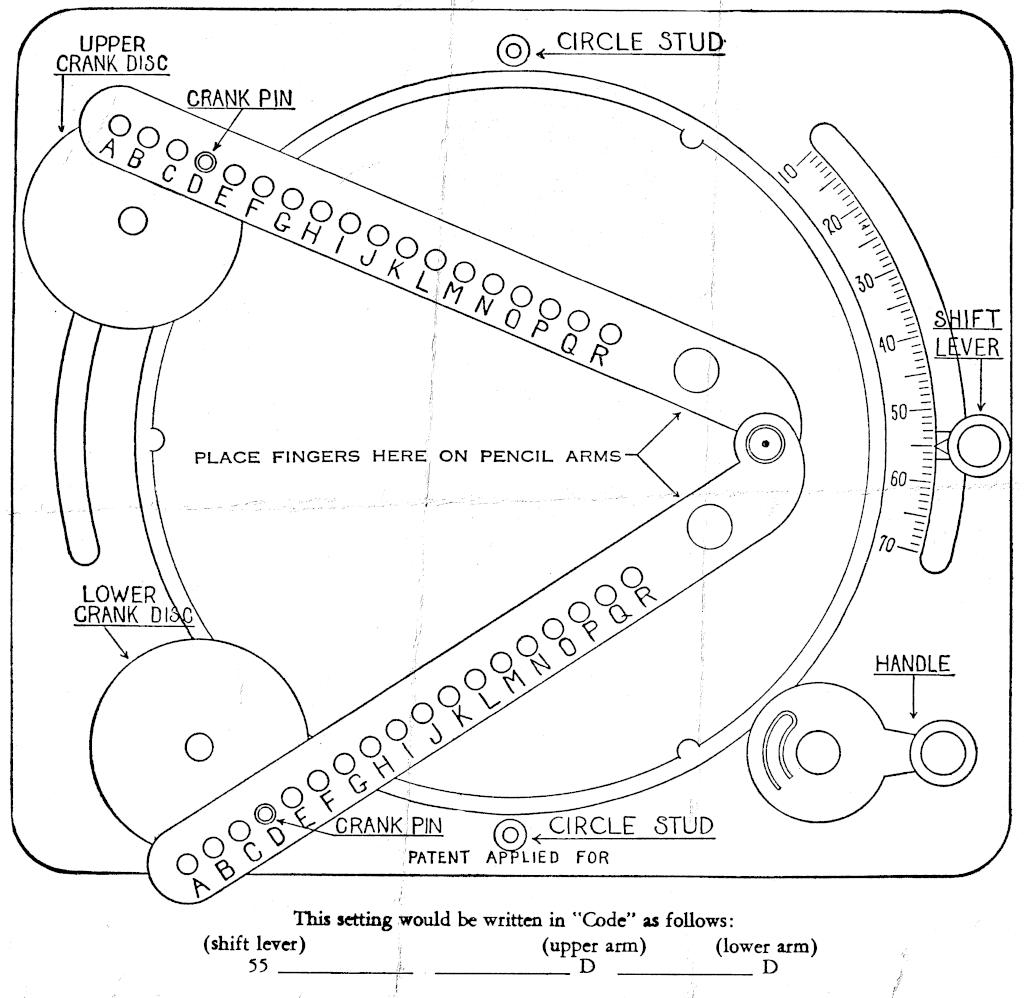

My eBay-acquired Magic Designer is quite beaten up, and doesn’t always produce accurate results. Here’s how one should look, from the instruction pamphlet:

As far as I’ve been able to work out, the parameters of the machine are:

If we model the toy with a fixed turntable:

Here’s a very simple model in Python that emits a hard-coded (but editable) pattern in HP-GL: Slightly imperfect Python simulation of the “HOOT-NANNY” (or Magic Designer) drawing toy (static local copy: hootnanny.zip). It doesn’t do anything with the fixed circle studs (yet)

… only to realize I don’t really like circular key grids.

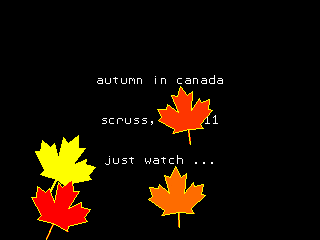

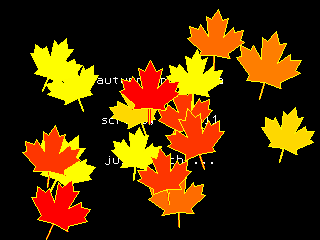

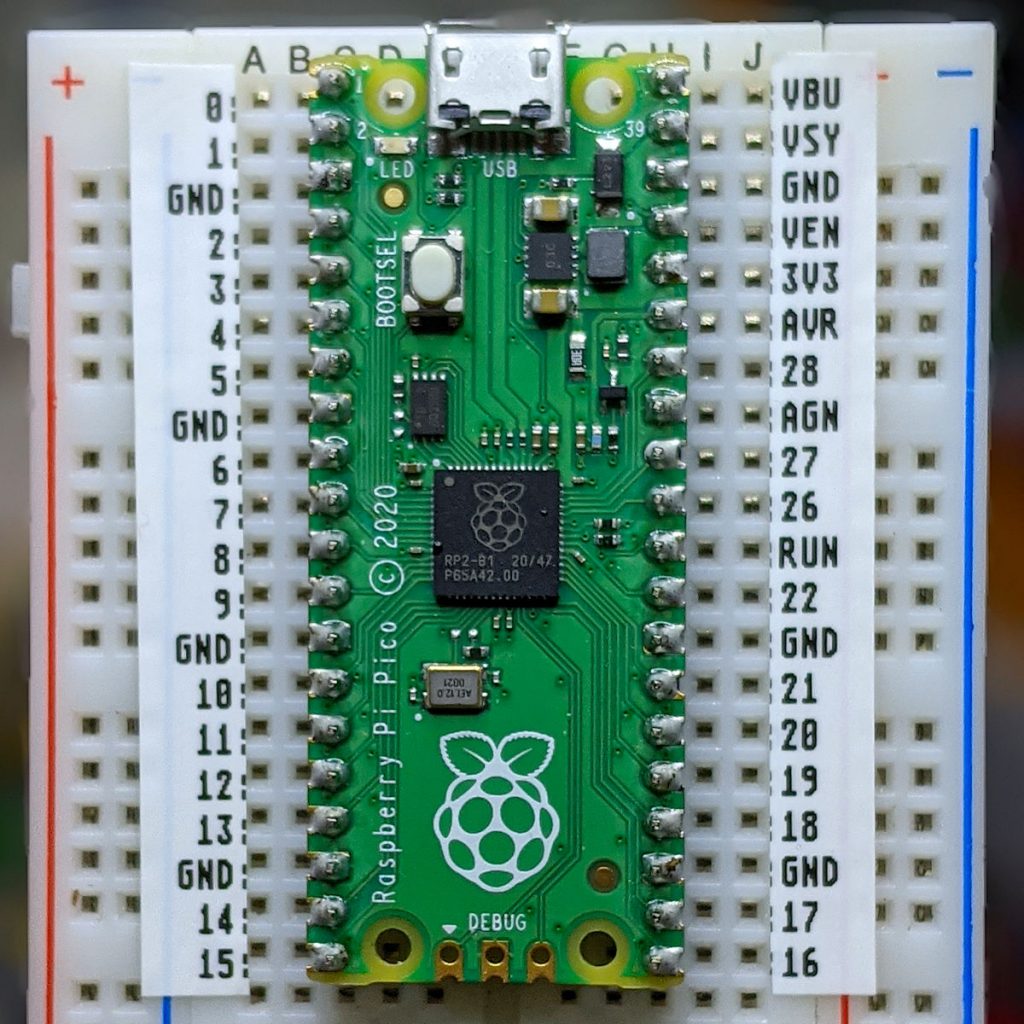

So I ported autumn in canada from OpenProcessing to PicoMite BASIC on the Raspberry Pi Pico:

The biggest thing that tripped me up was that PicoMite BASIC starts arrays at 0. OPTION BASE 1 fixes that oversight. It would have been nice to have OpenProcessing’s HSV colour space, and an editor that could handle lines longer than 80 characters that didn’t threaten to bomb out if you hit the End key, but it’ll serve.

Source below:

' autumn in canada

' scruss, 2021-11

' a take on my https://openprocessing.org/sketch/995420 for picomite

OPTION base 1

RANDOMIZE TIMER

' *** initialize polar coords of leaf polygon and colour array

DIM leaf_rad(24), leaf_ang(24), px%(24), py%(24)

FOR i=1 TO 24

READ leaf_rad(i)

NEXT i

FOR i=1 TO 24

READ x

leaf_ang(i)=RAD(x)

NEXT i

DIM integer c%(8)

FOR i=1 TO 8

READ r%, g%, b%

c%(i)=RGB(r%,g%,b%)

NEXT i

' *** set up some limits

min_scale%=INT(MIN(MM.HRES, MM.VRES)/8)

max_scale%=INT(MIN(MM.HRES, MM.VRES)/6)

min_angle=-30

max_angle=30

min_x%=min_scale%

min_y%=min_x%

max_x%=MM.HRES - min_x%

max_y%=MM.VRES - min_y%

CLS

TEXT MM.HRES/2, INT(MM.VRES/3), "autumn in canada", "CM"

TEXT MM.HRES/2, INT(MM.VRES/2), "scruss, 2021-11", "CM"

TEXT MM.HRES/2, INT(2*MM.VRES/3), "just watch ...", "CM"

kt%=0

DO

cx% = min_x% + INT(RND * (max_x% - min_x%))

cy% = min_y% + INT(RND * (max_y% - min_y%))

angle = min_angle + RND * (max_angle - min_angle)

sc% = min_scale% + INT(RND * (max_scale% - min_scale%))

col% = 1 + INT(RND * 7)

leaf cx%, cy%, sc%, angle, c%(7), c%(col%)

kt% = kt% + 1

LOOP UNTIL kt% >= 1024

END

SUB leaf x%, y%, scale%, angle, outline%, fill%

FOR i=1 TO 24

px%(i) = INT(x% + scale% * leaf_rad(i) * COS(RAD(angle)+leaf_ang(i)))

py%(i) = INT(y% - scale% * leaf_rad(i) * SIN(RAD(angle)+leaf_ang(i)))

NEXT i

POLYGON 24, px%(), py%(), outline%, fill%

END SUB

' radii

DATA 0.536, 0.744, 0.608, 0.850, 0.719

DATA 0.836, 0.565, 0.589, 0.211, 0.660, 0.515

DATA 0.801, 0.515, 0.660, 0.211, 0.589, 0.565

DATA 0.836, 0.719, 0.850, 0.608, 0.744, 0.536, 1.000

' angles

DATA 270.000, 307.249, 312.110, 353.267, 356.540

DATA 16.530, 18.774, 33.215, 3.497, 60.659, 72.514

DATA 90.000, 107.486, 119.341, 176.503, 146.785, 161.226

DATA 163.470, 183.460, 186.733, 227.890, 232.751, 270.000, 270.000

' leaf colours

DATA 255,0,0, 255,36,0, 255,72,0, 255,109,0

DATA 255,145,0, 255,182,0, 255,218,0, 255,255,0

You could probably use AUTOSAVE and paste the text into the PicoMite REPL. I used an ILI9341 SPI TFT LCD Touch Panel with my Raspberry Pi Pico along with some rather messy breadboard wiring.

Fun fact: the maple leaf polygon points are derived from the official definition of the flag of Canada.

This worked better than I expected. The tricky parts are trimming the edges and getting it them straight.

Here’s the image to print on your label maker:

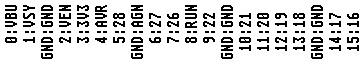

Consider the Adafruit PIR (motion) sensor (aka PIR Motion Sensor, if you’re in Canada). Simple, reliable device, but only runs from a 5 V supply. Yes, there are smaller PIRs that run off 3.3 V, but if this is what you have, you need to do some soldering. Annoyingly, the sensor on the board is a 3.3 V part, but the carrier was designed in Olden Tymes when King 5 V ruled.

You can try powering it from 3.3 V, but it’ll go all off on its own randomly as its own power supply won’t be supplying enough voltage. There are a couple of sites on how to modify these PIRs that either describe old kit you can’t get any more, or do it completely wrongly. Just one post on the Adafruit support forum gets it right.

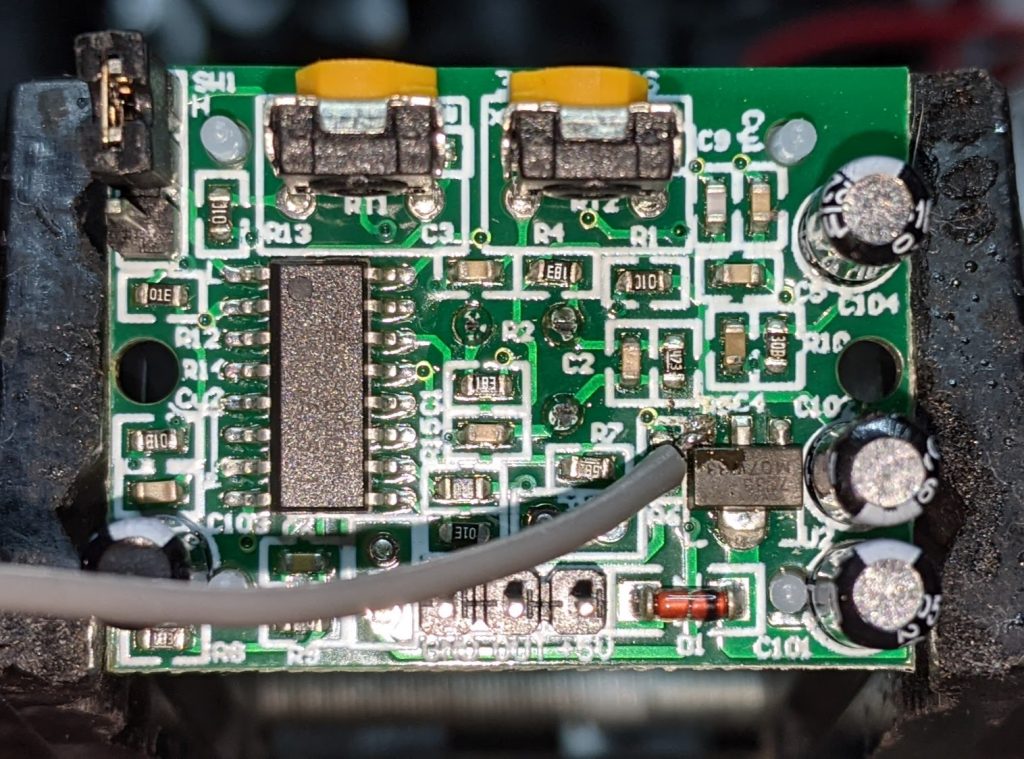

One way of doing this is to provide 3.3 V directly to the output pin of the voltage regulator, and ignore the 5 V power line entirely. The regulator’s a SOT89-3 part that looks a bit like this:

In the photo above, it’s flipped over. Whichever way it’s oriented, we want to put power directly into the Vout pin. There may be easier points to solder this to than a tiny surface mount pin (almost definitely one of the capacitors) but this has held for me.

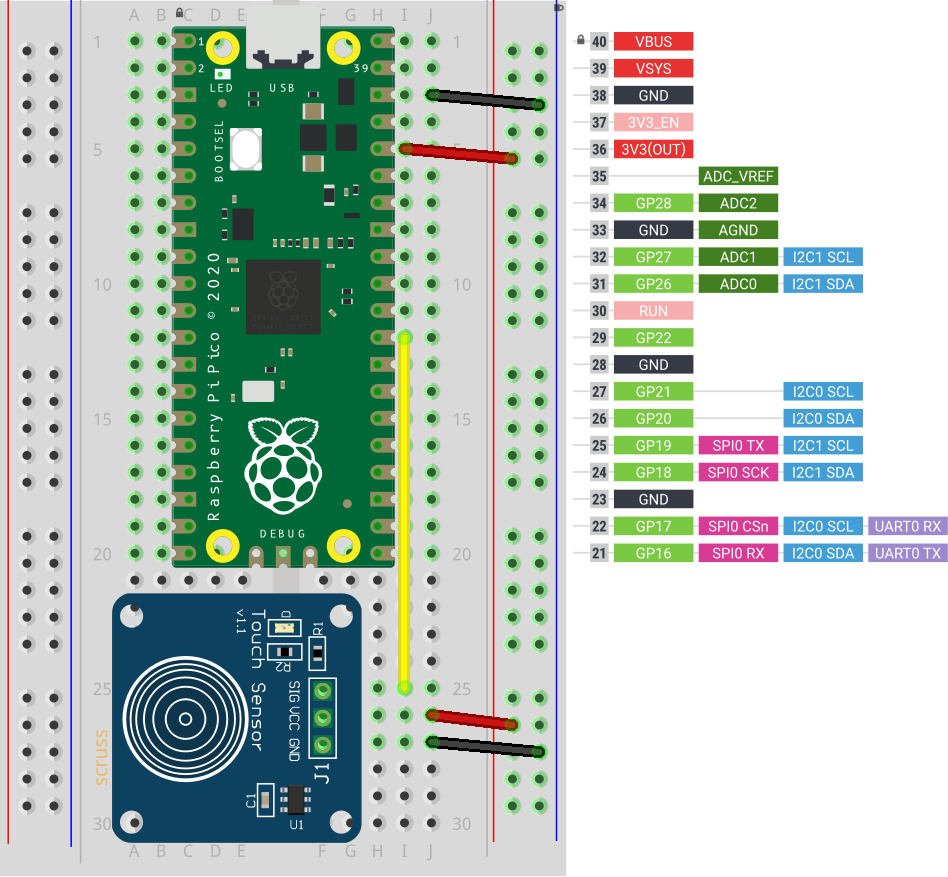

How to use it in MicroPython? Like the TTP223 capacitive touch sensors I looked at before, a PIR gives a simple off/on output, so you can use something like this:

from machine import Pin

from time import sleep_ms

pir = Pin(21, Pin.IN)

while True:

print("[", pir.value(), "]")

sleep_ms(1000)

value() will return 1 if there’s movement, 0 if not. There are trigger time and sensitivity potentiometers to fiddle with on the board if you need to tweak the output.

Just remember: don’t connect the 5 V power line if you make this mod. I’m not responsible for any smoke emitted if you do — but I can always sell you a replacement …

Notes

I’m remembering the time that Paul coloured a perfect square with a highlighter on their white family cat, Snowy. She had a pink side for weeks.

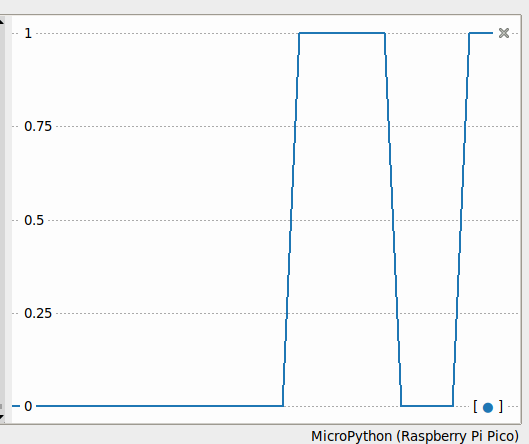

This is almost too trivial to write up, as the TTP223 does exactly what you’d expect it to do with no other components.

Breakout boards for the TTP223 capacitive touch sensor come in a whole variety of sizes. The ones I got from Simcoe DIY are much smaller, have a different connection order, and don’t have an indicator LED. What they all give you, though, is a single touch/proximity switch for about $1.50

Trivial code to light the Raspberry Pi Pico’s LED when a touch event is detected looks like this:

import machine

touch = machine.Pin(22, machine.Pin.IN)

led = machine.Pin(25, machine.Pin.OUT)

while True:

led.value(touch.value())

For the default configuration, the sensor’s output goes high while a touch is detected, then goes low. This might not be the ideal configuration for you, so these sensor boards have a couple of solder links you can modify:

And that’s all it does. Sometimes it’s nice to have a sensor that does exactly one thing perfectly well.

Almost no-one will need this knowledge, but I might need to remember it. In order to add Mini PPISD support to a RomWBW 3.01-supported system, you need to create a file called something like Source/HBIOS/Config/ZETA2_ppisd.asm (for yes, I’m using a Zeta SBC V2) containing:

#include "cfg_zeta2.asm" UARTCFG .SET UARTCFG | SER_RTS CRTACT .SET TRUE PPIDEENABLE .SET FALSE SDENABLE .SET TRUE PPPENABLE .SET FALSE PPISD .EQU TRUE

Running make from the top-level directory should create a ROM image called Binary/ZETA2_ppisd.rom for you to write to flash. Since my floppy drive isn’t feeling too happy, I had to resort to buying a TL866II Plus programmer to write the chip.

And it worked!

RomWBW HBIOS v3.0.1, 2021-03-12 ZETA V2 Z80 @ 8.000MHz 0 MEM W/S, 1 I/O W/S, INT MODE 2 512KB ROM, 512KB RAM CTC: MODE=Z2 IO=0x20 UART0: IO=0x68 16550A MODE=38400,8,N,1 DSRTC: MODE=STD IO=0x70 Sun 2021-03-14 17:47:13 CHARGE=OFF MD: UNITS=2 ROMDISK=384KB RAMDISK=384KB FD: IO=0x30 UNITS=2 SD: MODE=PPI IO=0x60 DEVICES=1 SD0: SDSC NAME=SD BLOCKS=0x003C7800 SIZE=1935MB Unit Device Type Capacity/Mode ---------- ---------- ---------------- -------------------- Char 0 UART0: RS-232 38400,8,N,1 Disk 0 MD1: RAM Disk 384KB,LBA Disk 1 MD0: ROM Disk 384KB,LBA Disk 2 FD0: Floppy Disk 3.5",DS/HD,CHS Disk 3 FD1: Floppy Disk 3.5",DS/HD,CHS Disk 4 SD0: SD Card 1935MB,LBA ZETA V2 Boot Loader ROM: (M)onitor (C)P/M (Z)-System (F)orth (B)ASIC (T)-BASIC (P)LAY (U)SER ROM Disk: (0)MD1 (1)MD0 (2)FD0 (3)FD1 (4)SD0 Boot Selection?

I was pleasantly surprised how easy it is to use a TL866 programmer under Linux. minipro does all the work, though. To write and verify the whole 512K Flash ROM, it’s:

minipro -p SST39SF040 -w ZETA2_ppisd.rom

The programmer supports over 16000 devices, of which around 10000 are variants (form factor, programming voltage, speed, OTP, etc). It’ll also verify over 100 different 74-series logic chips. It’s not a super cheap device (mine was a little over $80, from Simcoe Diy) but it does a lot for that price.

Next stop: try rebuilding BBC BASIC with RomWBW’s timer support included ..

So the Z80-powered doorstop that got so many people started with computers was launched 40 years ago.

My story is that we never had one: we had three, but only for a week each. It’s not that they failed, either. My dad, who ran the computer bureau at King George V Docks for the Clyde Port Authority, was Glasgow’s representative on the European Association for Data Processing in Ports (EVHA). The group was looking at ways for automating ship identification, efficient berthing and documentation handling.

All the ports had data centres, but most of the mainframe time was for predefined tasks such as dock-worker payroll. There wasn’t the budget for computer time to try some of the experimental projects that may have helped with port automation.

Several EVHA members were trying home computers unofficially, but many of them were too expensive to come in under expense account rules. These “big†micros required a business case and purchase order to buy. The ZX81, limited as it was, did fit in the expense budget and – equally importantly – fitted into my dad’s suitcase as he made his monthly trips to Europe.

The week before my dad was scheduled to leave, he’d buy a ZX81. Of course, it needed “testingâ€, something me and my brother were only too happy to do. At the end of the week, it would get packed up and on its way to Europe.

I’m not sure if the clandestine micros were ever actually used for controlling ship traffic (you get considerably fewer than three lives manoeuvring an LNG tanker), but more likely in simulation. I understand that the ZX81 was able to simulate the traffic management for the entire Port of Rotterdam for a while, at least until its RAM pack wobbled.

reposted from ZX81 40th Anniversary – Histories – Retro Computing

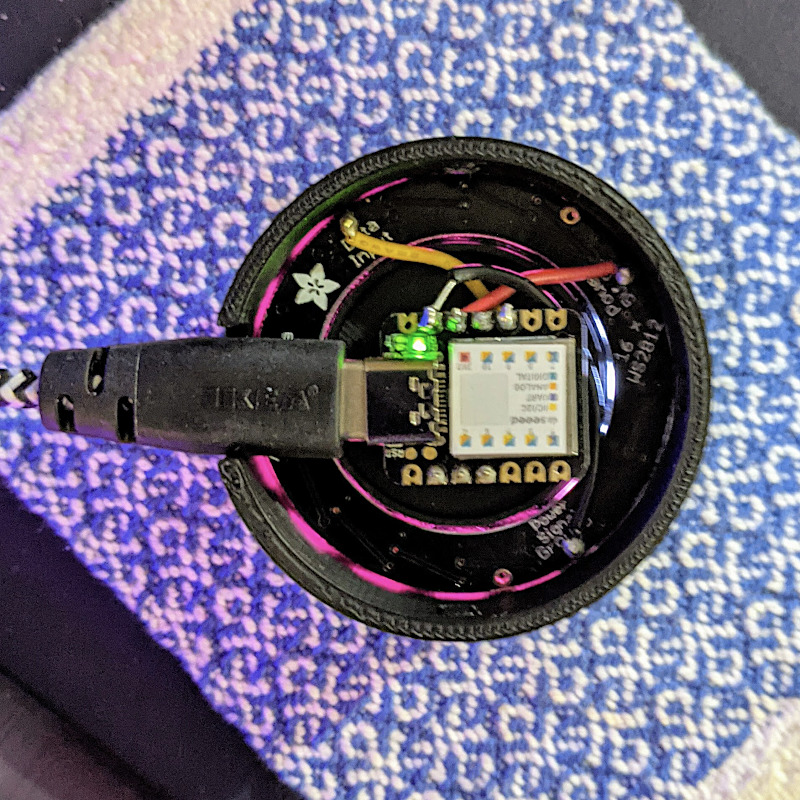

Tod Kurt’s QTPy-knob: Simple USB knob w/ CircuitPython is a fairly simple USB input project that relies on the pin spacing of an Adafruit QT Py development board being the same as that on a Bourns Rotary Encoder. If you want to get fancy (and who wouldn’t?) you can add a NeoPixel Ring to get an RGB glow.

The QT Py is based on the Seeeduino XIAO, which is a slightly simpler device than the Adafruit derivative. It still runs CircuitPython, though, and is about the least expensive way of doing so. The XIAO is drop-in replacement for the Qt Py in this project, and it works really well! Everything you need for the project is described here: todbot/qtpy-knob: QT Py Media Knob using rotary encoder & neopixel ring

I found a couple of tiny glitches in the 3d printed parts, though:

I bodged these by putting an indent in the middle of the diffuser, and filling the top D-shaft cutout with just enough Blu Tack.

Tod’s got a bunch of other projects for the Qt Py that I’m sure would work well with the XIAO: QT Py Tricks. And yes, there’s an “Output Farty Noises to DAC†one that, regrettably, does just that.

Maybe I’ll add some mass to the dial to make it scroll more smoothly like those buttery shuttle dials from old video editing consoles. The base could use a bit more weight to stop it skiting about the desk, so maybe I’ll use Vik’s trick of embedding BB gun shot into hot glue. For now, I’ve put some rubber feet on it, and it mostly stays put.

Hey! Unlike my last Seeed Studio device post, I paid for all the bits mentioned here.

It was inevitable:

brings you this wonderful creation, which plays the Nyan Cat theme forever, except it gets 20% faster each time. This is weapons-grade annoying (thank’ee kindly), so I’m not going to include a recording here. If you must hear an approximation, paste the RTTTL into Play RTTTL Online and enjoy.

# Raspberry Pi Pico RTTTL example

# nyan cat, but it gets faster

# scruss - 2021-02: sorry, not sorry ...

# Uses rtttl.py from

# github.com/dhylands/upy-rtttl

# Nyan Cat RTTTL from

# github.com/KohaSuomi/emb-rtttl/blob/master/rtttl/nyancat.rtttl

from rtttl import RTTTL

from time import sleep_ms

from machine import Pin, PWM

b = 90 # bpm variable

# pin 26 - GP20; just the right distance from GND at pin 23

# to use one of those PC beepers with the 4-pin headers

pwm = PWM(Pin(20))

led = Pin('LED', Pin.OUT)

def play_tone(freq, msec):

# play RTTL notes, also flash onboard LED

print('freq = {:6.1f} msec = {:6.1f}'.format(freq, msec))

if freq > 0:

pwm.freq(int(freq)) # Set frequency

pwm.duty_u16(32767) # 50% duty cycle

led.on()

sleep_ms(int(0.9 * msec)) # Play for a number of msec

pwm.duty_u16(0) # Stop playing for gap between notes

led.off()

sleep_ms(int(0.1 * msec)) # Pause for a number of msec

while True:

nyan = 'nyancat:d=4,o=5,b=' + str(b) + ':16d#6,16e6,8f#6,8b6,16d#6,16e6,16f#6,16b6,16c#7,16d#7,16c#7,16a#6,8b6,8f#6,16d#6,16e6,8f#6,8b6,16c#7,16a#6,16b6,16c#7,16e7,16d#7,16e7,16c#7,8f#6,8g#6,16d#6,16d#6,16p,16b,16d6,16c#6,16b,16p,8b,8c#6,8d6,16d6,16c#6,16b,16c#6,16d#6,16f#6,16g#6,16d#6,16f#6,16c#6,16d#6,16b,16c#6,16b,8d#6,8f#6,16g#6,16d#6,16f#6,16c#6,16d#6,16b,16d6,16d#6,16d6,16c#6,16b,16c#6,8d6,16b,16c#6,16d#6,16f#6,16c#6,16d#6,16c#6,16b,8c#6,8b,8c#6,8f#6,8g#6,16d#6,16d#6,16p,16b,16d6,16c#6,16b,16p,8b,8c#6,8d6,16d6,16c#6,16b,16c#6,16d#6,16f#6,16g#6,16d#6,16f#6,16c#6,16d#6,16b,16c#6,16b,8d#6,8f#6,16g#6,16d#6,16f#6,16c#6,16d#6,16b,16d6,16d#6,16d6,16c#6,16b,16c#6,8d6,16b,16c#6,16d#6,16f#6,16c#6,16d#6,16c#6,16b,8c#6,8b,8c#6,8b,16f#,16g#,8b,16f#,16g#,16b,16c#6,16d#6,16b,16e6,16d#6,16e6,16f#6,8b,8b,16f#,16g#,16b,16f#,16e6,16d#6,16c#6,16b,16f#,16d#,16e,16f#,8b,16f#,16g#,8b,16f#,16g#,16b,16b,16c#6,16d#6,16b,16f#,16g#,16f#,8b,16b,16a#,16b,16f#,16g#,16b,16e6,16d#6,16e6,16f#6,8b,8a#,8b,16f#,16g#,8b,16f#,16g#,16b,16c#6,16d#6,16b,16e6,16d#6,16e6,16f#6,8b,8b,16f#,16g#,16b,16f#,16e6,16d#6,16c#6,16b,16f#,16d#,16e,16f#,8b,16f#,16g#,8b,16f#,16g#,16b,16b,16c#6,16d#6,16b,16f#,16g#,16f#,8b,16b,16a#,16b,16f#,16g#,16b,16e6,16d#6,16e6,16f#6,8b,8c#6'

tune = RTTTL(nyan)

print('bpm: ', b)

for freq, msec in tune.notes():

play_tone(freq, msec)

b = int(b * 1.2)

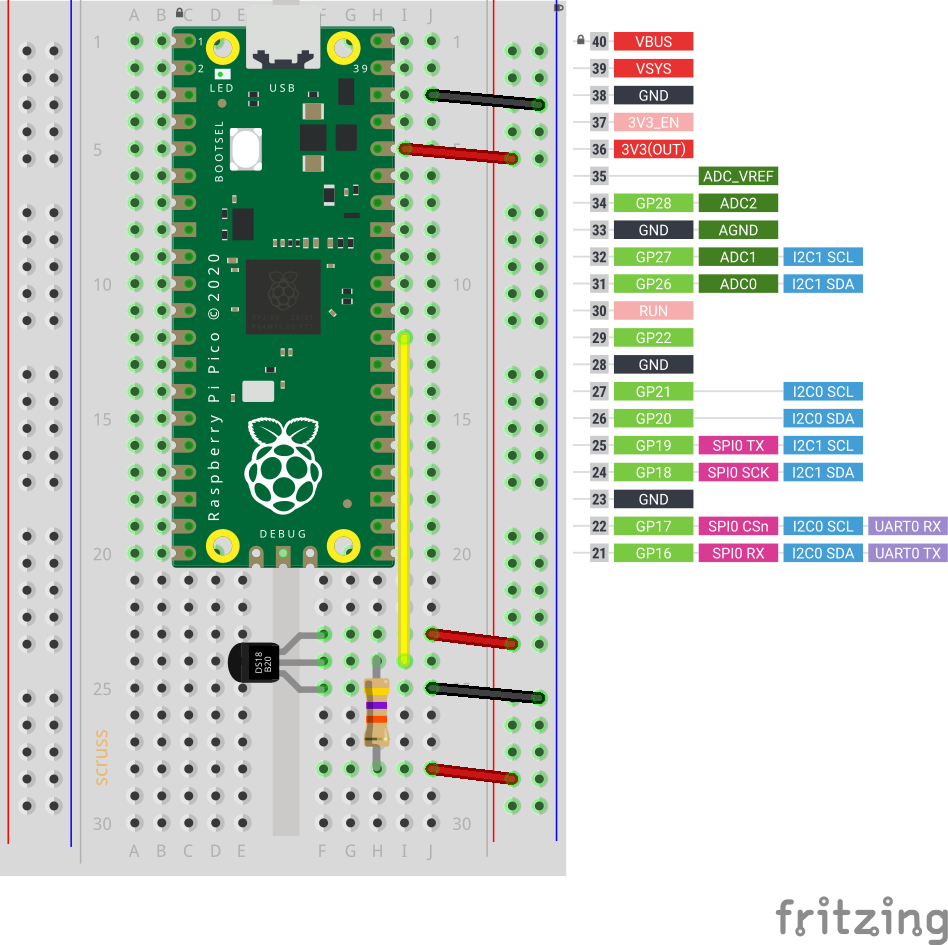

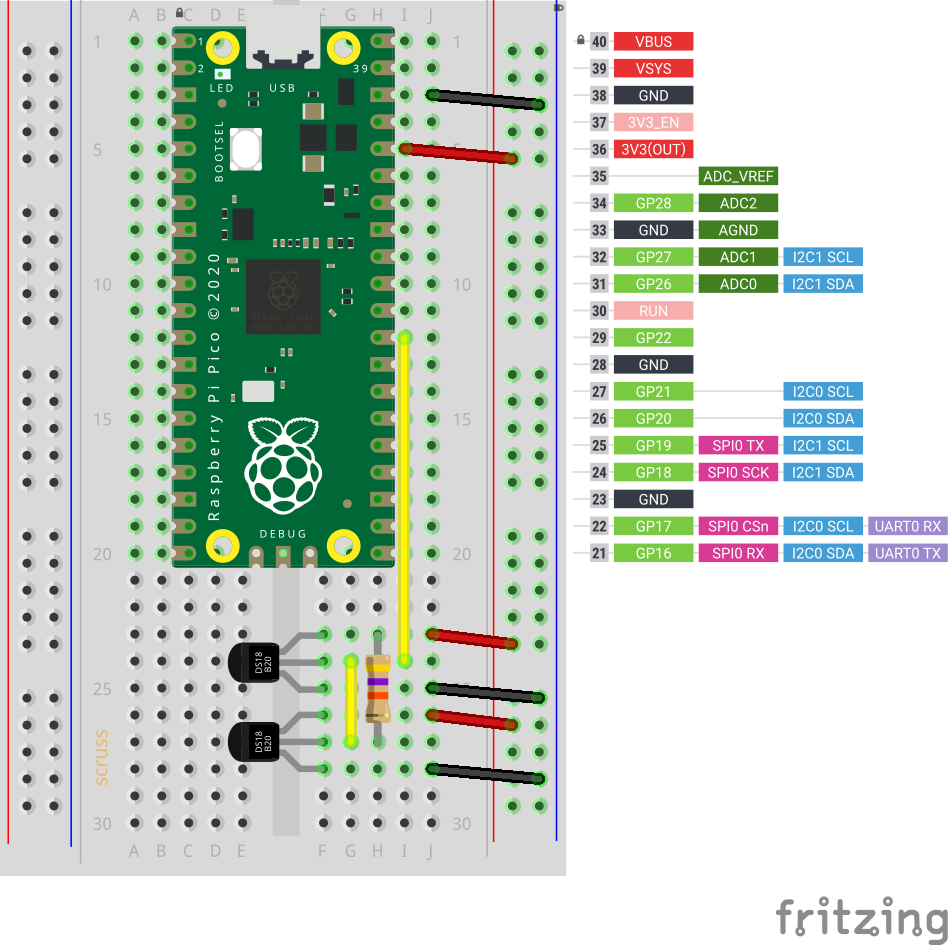

Updated: Thanks to Ben, who noticed the Fritzing diagrams had the sensors the wrong way round. Fixed now…

Hidden away in the Pico MicroPython guide is a hint that there may be more modules installed in the system than they let on. In the section about picotool, the guide has a seemingly innocuous couple of lines:

frozen modules: _boot, rp2, ds18x20, onewire, uasyncio, uasyncio/core, uasyncio/event, uasyncio/funcs, uasyncio/lock, uasyncio/stream

The third and fourth ‘frozen modules’ are a giveaway: it shows that support for the popular Dallas/Maxim DS18x20 1-Wire temperature sensors is built in. Nowhere else in the guide are they mentioned. I guess someone needs to write them up.

DS18x20 digital temperature sensors – usually sold as DS18B20 by Maxim and the many clone/knock-off suppliers – are handy. They can report temperatures from -55 to 125 °C, although not every sensor will withstand that range. They come in a variety of packages, including immersible sealed units. They give a reliable result, free from ADC noise. They’re fairly cheap, the wiring’s absurdly simple, and you can chain long strings of them together from the same input pin and they’ll all work. What they aren’t, though, is fast: 1-Wire is a slow serial protocol that takes a while to query all of its attached devices and ferry the results back to the controller. But when we’re talking about environmental temperature, querying more often than a few times a minute is unnecessary.

So this is the most complex way you can wire up a DS18x20 sensor:

and this is how it’s wired:

DS18X20 Pico

========= =========

VDD ? 3V3

/

--47 k?--

/

DQ ? GP22

GND ? GND

(47 k? resistor between DQ and 3V3 as pull-up)

Adding another sensor is no more complicated: connect it exactly as the first, chaining the sensors together –

The code is not complex, either:

# Raspberry Pi Pico - MicroPython DS18X20 Sensor demo

# scruss - 2021-02

# -*- coding: utf-8 -*-

from machine import Pin

from onewire import OneWire

from ds18x20 import DS18X20

from time import sleep_ms

from ubinascii import hexlify # for sensor ID nice display

ds = DS18X20(OneWire(Pin(22)))

sensors = ds.scan()

while True:

ds.convert_temp()

sleep_ms(750) # mandatory pause to collect results

for s in sensors:

print(hexlify(s).decode(), ":", "%6.1f" % (ds.read_temp(s)))

print()

sleep_ms(2000)

This generic code will read any number of attached sensors and return their readings along with the sensor ID. The sensor ID is a big ugly hex string (the one I’m using right now has an ID of 284c907997070344, but its friends call it ThreeFourFour) that’s unique across all of the sensors that are out there.

If you’re reading a single sensor, the code can be much simpler:

# Raspberry Pi Pico - MicroPython 1x DS18X20 Sensor demo

# scruss - 2021-02

# -*- coding: utf-8 -*-

from machine import Pin

from onewire import OneWire

from ds18x20 import DS18X20

from time import sleep_ms

ds = DS18X20(OneWire(Pin(22)))

sensor_id = ds.scan()[0] # the one and only sensor

while True:

ds.convert_temp()

sleep_ms(750) # wait for results

print(ds.read_temp(sensor_id), " °C")

sleep_ms(2000)

The important bits of the program:

That’s it. No faffing about with analogue conversion factors and mystery multipliers. No “will it feel like returning a result this time?” like the DHT sensors. While the 1-Wire protocol is immensely complicated (Trevor Woerner has a really clear summary: Device Enumeration on a 1-Wire Bus) it’s not something you need to understand to make them work.

Since I have the MidTBot ESP32 plotter running properly, I thought I should look at better ways of generating G-Code than using BASIC and lots of print statements. Ed Nisley — from whom I’ve learned a lot — always seems to be doing interesting things using the gcmc – G-Code Meta Compiler, and it looks like a useful little language to learn.

Here’s the code to make at least half of the above:

/*

osculating circles - scruss, 2021-01

gcmc version

Usage with midTbot / grbl_esp32:

gcmc osccirc.gcmc | grep -v '^G64' > osccirc.gcode

Or for SVG:

gcmc --svg --svg-no-movelayer --svg-toolwidth=0.25 osccirc.gcmc | sed 's/stroke:#000000/stroke:#C80022/g;' > osccirc.svg

*/

comment("osculating circles - scruss, 2021-01");

/* machine constants */

up = [-, -, 5.0mm];

down = [-, -, 0.0mm];

park = [5.0mm, 145.0mm, 5.0mm];

feedrate(6000mm);

/* model parameters */

centre = [100.0mm, 75.0mm];

r = 65.0mm;

lim_r = 3.0mm;

pr = r;

a = 0.0deg;

da = 6.0deg;

sc = 0.95;

comment("centre: ", centre, "; r: ", r, "; lim_r: ", lim_r, "; pr: ", pr, "; a: ", a, "; da: ", da, "; sc: ", sc);

/* counter / sense marker */

n = 0;

goto(up);

do {

centre += [(pr-r)*cos(a), (pr-r)*sin(a)];

goto([centre.x - r, centre.y]);

goto(down);

n++;

if (n%2) {

circle_cw(centre);

}

else {

circle_ccw(centre);

}

goto(up);

a += 360.0deg + da;

a %= 360.0deg;

pr = r;

r *= sc;

} while (r >= lim_r);

/* end */

comment(n, " circles");

goto(park);